The roofing industry dominates the North American market. It makes up over 90% of the demand in terms of both volume and value. The options for choosing industrial roofing can be overwhelming.

Industrial roofing systems provide superior protection against the elements. They also add significant value to your property. From a traditional metal roof to modern single-ply systems, there’s a perfect roofing system for every business.

Imagine a commercial roof that perfectly fits your business needs. Enhance your business aesthetic appeal while taking advantage of durability and minimal maintenance.

In this article, we’ll tell you everything you need to know about industrial roofing. Discover the best industrial roof options for your business today!

Types of Industrial Roofing

Industrial roofs tend to be more complex and intricate than residential roofs. This is because industrial applications have different requirements. This includes higher load-bearing capacity and superior fire resistance.

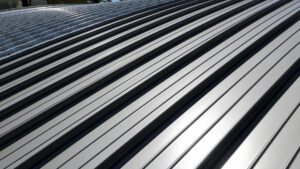

Metal Roofing

Metal roofs are among the most popular roof material choices in the industrial sector. They are an excellent choice for commercial and industrial buildings. This is because they are lightweight, durable, and fire-resistant.

Metal roofs come in different styles like standing seam metal roofs and corrugated metal roofs. This makes it easy to find a style that fits your building’s aesthetic appeal.

Single-Ply PVC Roofing

This is a great choice if you want superior protection against the elements. It provides excellent UV protection and is resistant to water, fire, and snow.

This type of industrial roofing requires minimal maintenance. Plus, it’s cost-effective and comes in different colors, so you can customize the look of your building.

Built-Up Roofing (BUR)

This is one of the oldest and most common industrial roof types. It’s composed of layers of asphalt material that create a waterproof barrier.

This type of roof is durable and can last for decades with minimal maintenance. Plus, it’s one of the most cost-effective roofing solutions for industrial applications.

Modified Bitumen Roofing

This type of roof combines asphalt and rubber. They are reinforced with polyester mats.

This makes it resistant to UV rays, extreme weather conditions, and chemical exposure. Plus, modified bitumen roofs are easy to maintain.

Thermoset (EPDM) Roof Membrane

These are usually made from ethylene propylene diene monomer (EPDM) reinforced with fiberglass fabric. They are an excellent choice for roofs that need protection. They protect against extreme temperatures, UV exposure, and weather-related damage.

It’s also a cost-effective option and can last up to 30 years with minimal maintenance.

Thermoplastic (PVC & TPO) Roof Membrane

This type of industrial roofing uses thermoplastic material. It’s highly resistant to UV rays and extreme weather conditions. It’s also a cost-effective option and can provide excellent energy efficiency for buildings.

Thermoplastic roofing can be easily installed. It requires minimal maintenance to remain effective. Plus, it comes in a variety of colors, so you can customize the look of your building.

Green Roofing Systems

These are excellent choices for industrial buildings that want to reduce their environmental impact. These roofs combine a waterproof membrane layer and several layers of vegetation. They provide insulation and extra protection from the elements.

They also help to improve air quality, reduce stormwater runoff, and provide habitat for wildlife. Additionally, green roofs can help reduce energy costs by providing natural shade and insulation.

Materials Used in Industrial Roofing

Industrial roofing comes in a range of materials. Depending on what your needs are, and the aesthetics you want to achieve, you can choose from a variety of options.

Metal

Metal roofing is the most popular choice for industrial buildings due to its durability and longevity. It’s made from steel, aluminum, or copper sheets.

This type of roofing is resistant to fire, weather, and UV rays. It’s also recyclable and can be energy efficient depending on the type of metal used.

Asphalt Shingles

These are a great choice for industrial buildings that need to protect against weather but don’t want an expensive roofing system. They are made from a mixture of organic and asphalt materials, making them lightweight and easy to install.

It’s also very affordable and comes in a range of colors and textures to suit any aesthetic needs. Asphalt shingles are also resistant to fire, wind, rain, and hail.

Polyvinyl Chloride (PVC)

PVC is a synthetic material that’s becoming more popular in industrial roofing due to its durability and affordability. It’s made from two or more layers of polyester threads coated with PVC and can come in a range of colors and textures.

This type of roofing is resistant to weather, fire, chemicals, ultraviolet rays, and impact. It also has excellent heat-reflective properties that can help keep your building cooler in hot climates.

Single-Ply Membranes and Rubber

This is a great option for industrial roofing due to its low cost and easy installation. They’re made from a single layer of rubberized material that’s heat-welded together at the seams to form an impermeable surface.

This type of roofing is highly resistant to fire, weather, and ultraviolet rays. It also has excellent insulating properties that can help keep your building cooler in hot climates.

Industrial Roofing Maintenance

No matter what type of roofing material you choose, it’s important to maintain it so that it can last as long as possible. Regular inspections and repairs are key to keeping your roof in good condition.

You should also make sure to clear away debris, such as branches or leaves, that can accumulate on the roof and cause problems. If you have a flat roof, it’s also important to check the drainage system regularly.

It’s important to inspect your roof in the spring and fall for any damage or wear and tear. A regular inspection schedule can help catch small problems.

You should also have a professional inspect your roof periodically to check for any potential problems that you may have missed. They can spot minor issues and repair them before they become major problems.

Need to Know More About Choosing an Industrial Roof?

Choosing the correct industrial roofing material for your property can be challenging. Thinking about the aesthetics, costs, functionality, and maintenance will help you make an informed decision.

If you’re interested in exploring more about your industrial roofing options, look no further than the Eagle Rivet Roof Service Corporation. We are a trusted and reliable provider of a broad range of roofing services. Contact us today and let our team of experts guide you in making the best roofing choice for your industrial building.

David Nietch graduated from Central Connecticut State University with a Bachelor of Science in Business Management and Organization. He has a strong background in positions which require experienced operation and project management as well as a strong attention to detail. David has a profound knowledge of concepts, competitive products, practices and process dealing with the roofing market. David excels at building highly effective working relationships with clients, technicians, managers and vendors.